Torque Speed Curve Mills For Mining

5 Guidelines for Gear Unit Selection

44 Catalog – Planetary Gearmotors P002 082 Series 5 Project planning procedure Guidelines for Gear Unit Selection Step 3: Selecting the appliion factors FS min Applica tionspecific service factor The appliionspecific service factor F s considers the typical load behavior with regard to the drive machine....

Measuring CNC mill power, speed and torque |Shane | Engineer

· · As expected the power grows linearly with speed but seems even worse than I thought with the mill drawing >300W at no load. Preload losses are normal, but this seems really out of whack. One thing at a time though I wanted to finish understanding the power / speed curve for my motor....

Grinding Mill Power

· Since as has already been mentioned, the critical speed is a criterion for the occurrence of many phenomena in a mill, it is perhaps of interest to mention that during the course of tests at various speeds, the configuration of the balls within the shell was observed through a perspex end cap, and, in the case of the smooth mill, centrifuging of the outer layer ....

Tip Speed Ratio provided by Kid Wind

use a wind speed in Miles/Hour and a tip speed in Meters/Second. This formula will help if you need to convert units of velocity: 1 meter per second equals miles per hour. Now that you've made all your measurements, you should be able to figure out your tip speed ratio (TSR). You already calculated the tip speed in the equation...

Torque vs Speed | daveballelectricgokart

· We then tried to measure the torque of the electric motor so that we could plot the Speed vs Torque curve, a linear curve that will tell us both the noload speed and the stall torque. The stall torque is the maximum allowable force that the motor can deliver. Our first effort to drive the kart failed because we had exceeded the stall torque....

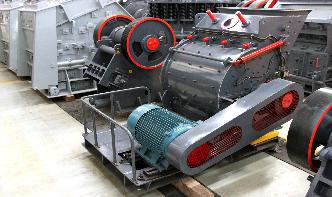

PE150×250 Ball Mill Torque Speed Curve | Crusher Mills ...

ball mill torque curve – rock crusher and mine solution . torque speed curves ball mill vfd motor. Heavy Industry(shanghai) is the best torque speed curves ball mill vfd motor manufacturers and suppliers, ....

torque calculation on a conveyor

· So motor torque = /=23Nm Taking a safety factor of 2 this torque becomes 46Nm. So the required motor power P=Txn/9550, where T=46Nm and n=N/i=1400/35=40RPM (speed at the gearhead output shaft) P= I can not understand where i have to use the torque speed curve as you are advising me....

True Mechanical Torque vs Calculated Torque

Purple plot: True Mechanical Torque on the shaft, the output of Binsfeld's TorqueTrak telemetry system. Green plot: Calculated Torque using motorload calculations. Blue plot: What the customer calls "Top Motor Speed.". Left Axis is the Percent Torque, where full scale = 215 metric tonsmm. Right Axis is the shaft speed in RPM, although ......

torque speed calculation for ball mill

calculation of torque on grain mill. torque speed calculation for ball mill, TECHNICAL NOTES 8 GRINDING R P King Mineral Tech TECHNICAL NOTES 8 GRINDING R P King 82, Figure 83 Simplified calculation of the torque, The effect of varying mill speed on the power drawn by the mill is DC Motor Torque/Speed Curve, dW/dt is the rate of doing work, or power P When a ....

torque speed curves ball mill vfd motor | worldcrushers

· A motor VFD system speedtorque curve, will vary depending on the motor, . used grinding mills for sale; ball mill knowledge in malaysia; Starting Torque for VFD Drive – bulkonline Forums Most VFD's can provide your higher nominated starting torque than motor nameplate if the . you shift the breakdown torque curve toward the ....

Grinding Mill Power

· · Since as has already been mentioned, the critical speed is a criterion for the occurrence of many phenomena in a mill, it is perhaps of interest to mention that during the course of tests at various speeds, the configuration of the balls within the shell was observed through a perspex end cap, and, in the case of the smooth mill, centrifuging of the outer layer ....

KILN DRIVE APPLICATION CONSIDERATIONS

Torque pulsations and induced vibrations and their effect on the mechanical drive train components are reviewed. Index Terms — Kiln appliion, drive control, torque INTRODUCTION Selection and appliion consideration for drives and motors powering the kiln is a continuously evolving process. The latest variable speed control...

Characteristics of wind Power Systems

Components of a wind mill . Capacitor Factor • Capacity factor of a wind power generator is defined as for a site with an average wind speed of 7 m/s, c f ... Torquespeed curve of induction machine • Mechanical power delivered to the shaft: • Mechanical torque:...

3

A case study from the Western Australian mining ... resistance to ensure the mill motor would develop ample torque to accelerate the mill. The nominal three phase voltage level of the system is run at ... An important point is to note the selected motor's torque speed curve, as different makes and types of motors have differing curves....

TMEIC | Technology, Products and Automation Solutions for ...

is focused on determining optimum speed setting. Controlling Torque. In addition to controlling speed, you also have to consider torque requirements. Mine machin ery torque profiles are all over the map some wildly swinging, some smoothly predictable. Torque control fo cuses on providing adequate torque for the load at all op...

Load types and characteristics

· The envelope might be a blend of quadratic torque from standstill up to minimum speed, constant torque in the continuous operating range and inverse torque in field weakening range (narrow range for compressors, but fairly wide for some other appliions). All these figures 1a, 1b and 2 show the load torque versus speed....

DC Machines

control speed and torque regulation. However, their appliion is limited to mills, mines and trains. As examples, trolleys and underground subway cars may use dc motors. In the past, automobiles were equipped with dc dynamos to charge their batteries....

Ball Mill Load Torque Curve

Coal Hammer Mill Torque Curve. speed torque curve for jaw crusherGold Ore Crusher Attached is the speed vs torque curve for the load Hammer Mill grinding Hard coal, mpf 1310 coal mill in Read more ball mill torque curve. Soft Start For Ball Mill Appliion Soft Starters. Mar 25, 2007 Also torque and speed curves are not available. The Lock ......

Torque Speed Characteristics of Induction Motor ...

FIGURE 1 Induction motor torquespeed characteristic curves.. Figure 2 showed the equivalent circuit for the stator. We can simplify our calculations by replacing it with a Thevenin's equivalent so that we do not have parallel branches in the equivalent circuit. Figure 3 shows a Thevenin's equivalent of the stator....

PitchControlled VariableSpeed Wind Turbine Generation

TSR (curve as shown in Figure 2), where the TSR is the tipspeed ratio; that is, the ratio between the linear speed of the tip of the blade with respect to the wind speed. It is shown that the power coefficient CP varies with the tipspeed ratio. It is assumed that the wind turbine is operated at high CP values most of the time....

SAG Mill Grinding Circuit Design

· Mill operating conditions including mill speed (for circuits with variablespeed drives), ... SAG Mill Operation Example. Kidston Gold Mines is a 14 000 tonnes per day rated operation loed 280 kilometers west of Townsvilie in Queensland. ... and kNm from base to top speed. Maximum accelerating torque is 175 percent....

Grinding Mill Power

· Since as has already been mentioned, the critical speed is a criterion for the occurrence of many phenomena in a mill, it is perhaps of interest to mention that during the course of tests at various speeds, the configuration of the balls within the shell was observed through a perspex end cap, and, in the case of the smooth mill, centrifuging of the outer layer of the balls was not observed at ......

How to read the characteristics of a DC motor? | Rotero

Figure 1. Motor characteristic curves of a brushed DC motor. To illustrate, for the motor in Figure 2, delivering a torque of 25 mNm, the corresponding speed is 2000 rpm, at which the motor draws approximately of current. This chart also tells us that this torque, speed and power are not optimum values for this type of motor....

Variable speed drive for hoist in mining industry

Then motor accelerates according to set accelerating curve. Motor output torque is determined by load and set accelerating time, about times of rated torque. Load torque is 1 time of rated torque, accelerating torque is times of rated torque. Resistance of physical system and output torque of motor increases with speed rising....

Motor Calculations

Torque Speed Curves One commonly used method of displaying motor characteristics graphically is the use of torque speed curves. While the use of torque speed curves is much more common in technical literature for larger DC machines than it is for small, ironless core devices, the technique is applicable in either case. Torque speed...