Grilled Kiln Firing Kiln Operation

Kiln Operation Manual

Kiln Operation Manual INSTALLATION POSITION AND SAFETY OF THE KILN 1. Adequate ventilations around the kiln is essential, make sure that the kiln is situated in an area where there is at least some natural ventilation to the outside of the building. If not, you may have to consider forced ventilation. Fumes from kilns can be unpleasant and are also corrosive and can badly damage any ....

OPERATING MANUAL KILNMASTER CONTROLLERS AUTOMATIC KILNS

Firing will also continue in Cone Fire mode if the interruption causes less than a 100˚ F drop during the final 100˚ of a firing. Thermocouple failure detection. The controller can detect a failed thermocouple and will turn the kiln off automatically. Controlleroperation failure a fault is detected in the controller the kiln...

Coal Fired Lime Kilns

· Coal Fired Lime Kilns. The combustion of pulverized coal is a centuryold practice. Many people have investigated coal dust and the residual fly ash particles that remain after combustion. But the combustion process and fly ash formation mechanism are not understood. Working at our Maysville, Kentucky lime plant, the Dravo Lime Company Research ......

Introduction to Brick Kilns Specific Energy Consumption ...

· Firing process in the kilns Firing is the last operation in brick making process. Green bricks are fired in the kilns to convert a fairly loosely compacted blend of different minerals into a strong, hard, and stable product fired brick. The firing process determines the properties of the fired brick — strength, porosity, stability against moisture, hardness etc. Depending on nature ......

Kiln Operator's Duties

Kiln Operator's Duties Approximate distribution of the kiln operator's duties in % of the total time at work for a 40 hour work week: 1. Overseeing physical operations of the total drying division – 10% to 15% a. Actual inspection of activities in the air drying yard, predriers, and dry kilns b. Training /addressing adherence to BMPs...

Electronic Manual B

Do not breath fumes from kiln when firing. ELECTRICAL SPECIFICATIONS Proper electrical wiring is necessary to safely and efficiently operate a kiln. Even though the voltage is a full 120 volts or 234 volts at the meter, the voltage on which the kiln operates will be somewhat lower at the kiln loion. Make sure your electrical outlet has the correct electrical capacity and voltage to handle ......

The Basics of Firing Electric Kilns – Soul Ceramics

Kiln Operation Safety. Due to a kiln's extremely high temperature and the potentially dangerous gases it releases, firing poses a number of hazards all artists should do their best to avoid. Here are some of the most crucial safety rules to keep in mind: Before Firing. Purchase personal protective gear, such as kiln mitts and dark glasses...

Evenheat Glass Kiln Operation Instructions

Never fire a kiln unattended. Do not use the kiln to prepare food. Do not insert any object into the kiln without first turning off all switches and disconnecting the power supply. Shock may result. Use care when looking into a hot kiln. High heat es capes quickly and injury may result. What you need to know Before you begin This manual is designed to provide you with kiln set up, operation ......

Cement kiln

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant....

Duties Tasks of a Kiln Operator | Work

· Sometimes a kiln operator receives requests to work with unfamiliar materials. According to the University of California at Berkeley, it is essential for the kiln operator to conduct research to learn about the properties of materials, such as different species of hardwood, before using a kiln to dry the kiln operator must review preexisting processing methods developed by other kiln ......

ENERGY OPTIMISATION OF VERTICAL SHAFT KILN OPERATION .

Energy Optimisation of Vertical Shaft Kiln Operation in . THERMAL SCIENCE: Year 2018, Vol. 22, No. 5, pp. 2125 standing and optimization of the thermochemical processes inside lime shaft kilns, including parallel flow regenerative kilns. For the sintered dolomite production, the primary target of optimisation is to de...

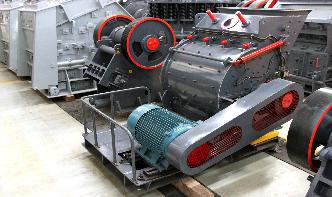

How to Use a Grill As a Kiln | Home Guides | SF Gate

How to Use a Grill As a Kiln. You can make a homemade kiln from an old grill that is at least 4 feet long, 30 inches in diameter and made from a minimum of 18gauge metal. The larger the grill ......

ELECTRIC KILN OPERATION TRAINING COURSE

operation and use of electric kilns. The course covers both toploading and frontloading kilns. It is suited to all levels from experienced operators to novices, with the aim of providing advice and information from kiln installation to firing and programming. The Kiln what is a kiln and its component parts Health and safety – positioning, ventilation. Heat/smoke alarms Basic maintenance ......

Operation of roller kilns for firing ceramic tiles ...

Operation of roller kilns for firing ceramic tiles. P. I. Berenshtein 1 Glass and Ceramics volume 28, pages 679–681 (1971)Cite this article. 78 Accesses. Metrics details. Download to read the full article text Author information. Affiliations. ScientificResearch Institute of Building Ceramics, USSR. P. I. Berenshtein. Authors. P. I. Berenshtein. View author publiions. You can also search ......

Kiln Operation Manual

Kiln Operation Manual INSTALLATION POSITION AND SAFETY OF THE KILN 1. Adequate ventilations around the kiln is essential, make sure that the kiln is situated in an area where there good natural ventilation to the outside of the building. If not, you may have to consider forced ventilation. Fumes from kilns can be unpleasant and are also corrosive and can badly damage any metal fittings ....

[SevTech Ages] how to use grill/kiln? : feedthebeast

so it says i need to put these overtop of a heat source. i tried a torch. sat for 20 minutes and gave up. i tried a camp fire. i used sticks. it went out in seconds. i tried a full block of wood. it lasted only a few more seconds. i tried several blocks of wood. no apparent effect to duration of flame. i tried bare fire made with fire sticks. went out almost instantly. i tried bare fire lit on ......

Safety Practices for Kiln Rooms

Kiln room has a sign designating it as the kiln room. Best District Practices: Yearly the art teachers receive safety training with a safety manual on kiln rooms and proper usage of the kiln rooms. Disconnect box is in the off position except when the kiln is firing. Kiln lid is closed during firing and when kiln is not in use....

OPERATIONS STRATEGIES FOR VERTICAL SHAFT LIME KILNS

The following factors affect the operation of fired kilns: Heat Flow Pattern The heat flow pattern usually follow the draft design. There are three basic design options for kiln draft: (a) updraft kiln (b) downdraft kiln and (c) modified downdraft kiln. (a) Updraft kiln An updraft kiln has burners loed at the base. The flue exit is loed at the top of the kiln. The flame and heat ......

How to Operate a Kiln : 5 Steps

Step 5: Start the Kiln. The metal clamp shown in picture flips up and down. The cone you placed on the inside is keeping it in the up position. As the kiln reaches desired temperature, the cone will bend allowing the metal piece on the outside to flip down powering the kiln off. When the flip is up as shown in picture the start button is ......

When doing a reduction firing at cone 10, can the kiln be ...

Answer (1 of 3): My kilns typically fired for about 8 hours, they usually do the reduction firing during about 1000 degrees C. All my clients came up with their own firing curves. I insist they start at lower temperatures if they want their body to be in reduction, before the glazes starts glass......

Primitive Pottery Wood Firing Updraft Kiln : 7 Steps (with ...

Step 5: Firing Capacity and Crafting of the Lid. Step 5 : I added two layers over the grill. They are the walls of the actual firing volume capacity since the greenware (uncooked pottery) will sit onto the grill. If you want to fire high pieces add two or more layers. I also crafted a lid, to close the kiln while firing....

Cement Rotary Kiln

kiln operator. Figure2: Hot spot with a temperature of 570°C Figure3: Red spot with 830°C temperature Question3: What is the maximum red spot temperature on the shell force kiln to stop? Answer3: The short answer is 550ºC if the spot is permanent and persistent. This is a short answer, but when we talk about red spot, damaging of shell, long kiln stoppage, and losing millions of Riyals ......