Quarry Sand In Compaction Pile

SCP

SCP Sand Compaction Pile. AFF Above Finished Floor; Uperiod;Nperiod;Operiod; Unless Noted Otherwise; SS Stainless Steel; RCP Reflected Ceiling Plan; KASM Kiwis Against Seabed Mining; DRL Distributed Robotics Laboratory; RIC Rapid Impact Compaction; NDG Nuclear Density Gauge; CRR Cyclic Resistance Ratio; CP Chicago Pile; TLWP Tension Leg Well ....

JPHA

PROBLEM TO BE SOLVED: To reflect compaction effects in driving a pile on the design of a sand compaction pile. SOLUTION: An insitu ground N value N0 is found, a target N value N1 after the improvement is set, and the maximum void ratio eMAX and eMIN are found from a fine grain content ratio Fc (%) in a step 1. In a step 2, a relative density Dr0 and the void ratio e0 of ....

Volume of a Pile Calculator

Estimate the volume of an excavated pile of material in cubic yards. If you look at the second image, the footprint, length A is not the overall length. If you subtract that from the total length and add both ends, you end up with a cone that has a diameter that is equal to length B. The calculation is done in two parts. The volume of the cone is calculated as: V = 1/3 * π * R² * H V = the ......

How to compact sand and dirt in preparation for pavers ...

· In Summary, upright rammers are used for a more direct and focused compaction on cohesive soils. Mainly used in trenches, around pipes/manholes and in areas where other compactors won't fit. Vibrating plates are used for a more evenly spread compaction on granular soils. Mainly used for bedding sand and road base where an even surface is ......

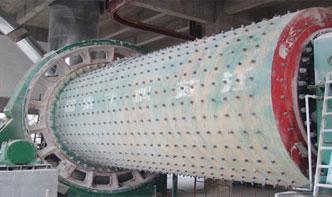

Marine Sand Compaction Pile Method and SEMW Jumbo Vibro

Sand Compaction Pile (SCP) Method, developed in Japan in 1950 and widely used in Japan and Korea, is the right solution. SCP is one of the methods to strengthen the soft ground and to obviate or reduce the dredging for seawall construction. Typical section of quay wall supported by SCP. Sand Compaction Piles . One Barge with three SCP Leader. SCP improves the ....

Sand Compaction Pile

Sand compaction pile method. The equipment of the sand compaction pile (SCP) method resembles that of sand drain installation. When the tip is penetrated to a predetermined depth, the equipment is withdrawn, leaving a loose sand pile of predetermined length through its mandrel. Then, with the aid of a vibrator at the top of the mandrel, the mandrel compresses the sand ....

A multiproxy analysis of sandy soils in historical slash ...

· All sites are loed on sandy (loamy sand to sandy loam) soils, as indied by the grain size analysis. The Apyr layers are characterized by a remarkably high carbon content, varying from to %. The carbon content of Apyr layers is –% higher than that of the organomineral horizons below and above, including the plough layers, and similar to the carbon content of EApyr. The ......

Quarry Sand In Compaction Pile

Quarry Sand In Compaction Pile. High Energy Impact Compaction Black Geotechnical Four hectare office development in port melbourne on 2m of sand fill over loose compaction of loose sand up to 7m deep for the jupiters convention hectare site at nelly bay, magnetic island, on 27m of sandclayey sand fill developed with twelve 34 level buildings on high level strip ......

GROUND IMPROVEMENT

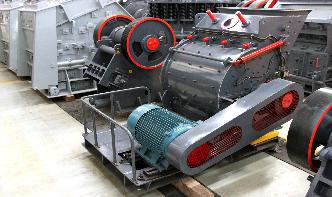

Utilization of a top pile driving vibrator in a vertical mode is less efficient. •Utilization of the concept of frequency of vibrofloat matching that of natural frequency of insitu soil is also done in vibrocompaction (Eg: Miller Resonate compaction technique). •Vibroreplacement uses the same equipment as in vibrocompaction and uses water/air as the jetting medium, and ....

quarry sand in compaction pile

quarry sand in compaction pile. Vibro Compaction Franki Africa. Vibro Compaction is a technique that compacts granular soils and rearrange the soil particulars into a denser state. The compaction is attained using depth vibrators typically suspended from a crane or mounted on piling equipment. Behaviour of compaction piles made from reinforced . Behaviour ....

BEHAVIOUR OF COMPACTION SAND PILE AND STONE COLUMN .

compaction sand pile and stone column is limited to size of plate used is 25mm thick and 50mm in diameter. Test Setup A typical arrangement of the experimental set up is shown in Fig. 1. Both compaction sand pile and stone column are inserted into the soil sample by displacement method. Load was applied through a proving ring at a constant strain rate of /minute. Displacement ......

Effect of Quarry Waste on SelfCompacting Concrete ...

· This paper presents the results of the experimental work conducted to study the effect of quarry waste on selfcompacting concrete containing binary cementitious blends of fly ash and cement. For this purpose nine trial mixes were prepared, where the percentage replacement of river sand by quarry waste was 0%, 10%, 20%, 30#x25;, 40#x25;, ....

CiteSeerX — Optimum utilization of Quarry dust as partial ...

River sand is most commonly used fine aggregate in concrete but due to acute shortage in many areas, availability, cost environmental impact are the major concern (Ahmed, 1989). To overcome from this crisis, partial replacement of sand with quarry dust can be an economic alternative. In developing countries like India, quarry dust has ......

Vibro compaction | Keller North America

During vibro compaction, clean sand backfill is typically added at the ground surface to compensate for the decrease in soil volume from the densifiion process. The vibratory energy reduces the intergranular forces between the soil particles, allowing them to move into a denser configuration, typically reaching a relative density of 70 to 85%. The treated soils have increased density ......

compaction factor for quarry dust

compaction factor for quarry dust. An Experimental study on Effects of Quarry Dust as Partial test compaction factor The set of series are M20 M25 grade of concrete with 10 20 30 40 50 and 60 percentage replacement of quarry dust tested for 7 days and 28 days is studied and the results are presented 50 replacement of sand by quarry dust...

Quarry Sand In Compaction Pile

· Quarry Sand In Compaction Pile. 1the pile moves downward under its weight plus the weight of the vibratory hammer. an amplitude of at least one inch is usually required to cause enough soil disturbance to achieve pile driving. vibratory compaction works well as the soil disturbance due to vibration causes the soil particles to move into a denser....

Ground Improvement Business/Fudo Tetra Corporation

Pioneer of the Sand Compaction Pile Method In 1956 Fudo Tetra was first in the world to develop the sand compaction pile method, which is now the most common method of ground improvement. We have continued research and development since that time, and now as experts in geotechnical engineering we have a wealth of design and implementation technologies and long experience in ....

Sand Compaction Pile Technology and its Performance in ...

The sand compaction pile (SCP) method is a method of improving soft ground by means of installing wellcompacted sand piles in the ground. It combines such fundamental principles of ground improvement as densifiion and drainage. It can be applied to all soil types, from sandy to clayey soils, and it has therefore been widely used in Japan for improvement of soft ground. In sandy ground, the ......

Quarry Sand In Compaction Pile

Quarry Sand In Compaction Pile. Sand Compaction Pile Equipments sand copaction pile machine,air compress. sand copaction pile machine air compress, sand compaction pile equipment soil compaction is the process in which a stress applied to a soil causes . Chat now; Get Price And Support Online; . Using Of Quarry Dust In Bored Pile Concrete. Usage Of Granite Dust In Place Of Sand For ....

What are sand piles?

Sand Piles : (A method of soil improvement) Sand compaction piles consists of driving a hollow steel pipe with the bottom closed with a collapsible plate down to the required depth; filling it with sand, and withdrawing the pipe while air pressure......