Mill Process Of Cement

Vertical roller mill for raw Appliion p rocess materials

Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation...

Process of cement ball mills | Mining, Crushing, Grinding ...

· Process of cement ball mills . BY limingloveshe | September 7th, 2011 . 0. Traditional methods, the ball mill during the processing of materials usually can play two effects, one is broken effect, one is the grinding effect. General sense, breaking effect can be broken using other ancillary equipment to ground level of the direct effect of the impact ....

Overview of our mills · Christian Pfeiffer

More efficient grinding processes. Overview of all of our mills. Mills for grinding cement, coal, or minerals: Christian Pfeiffer designs and builds grinding plants for many different feed materials and finished products. Our mills are as varied as the requirements of our customers. Ball mills, vertical mills, compact mills, jet mills or roller ......

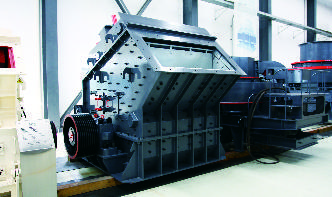

Ball Mill Roller Press for Cement Grinding Process

1. Roller Press Cement Pre Grinding System. The most noticeable feature of the roller press cement pre grinding system is that the fine material power ground at the middle part of the roller will be sent to the ball mill for further grinding. The cement grinding process in this system is rather simple with less equipment required....

Reducing energy consumption of a raw mill in cement ...

· Cement production in the world is currently about billion ton per year. About 2% of the electricity produced in the whole world is used during the grinding process of raw materials .While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size reduction ....

What Is The Process Of Cement Grinding | Crusher Mills ...

Cement crushing plant,process line,mill operation,grinding . Ball mill is the most popular cement grinding machine used for grinding cement into powder in process line. Ball mill is an excellent tool to select mine or grind a . question and answer for cement grinding process in south . Posts Related to question and answer for cement grinding process in south africa. question and answer ......

Three Quick Tips For Manufacturing Of Cement | Building ...

· Manufacturing Of Cement. Manufacturing Of Cement. by any one of the two methods : (i) Dry process, and (ii) Wet process. In both these processes the three distinct operations of (a) Mixing, Ball mill (b) Burning, Rotary kiln and (c) Grinding are carried out. 1. Dry process....

Manufacturing of Portland Cement – Process and Materials ...

· Fig. 3. cement mill section in dry process It is important to note that the strength properties of cement are considerably influenced by the cooling rate of the clinker. The rate of cooling influences the degree of crystallization, the size of the crystal and the number of ....

Process for using mill scale in cement clinker production ...

· A process for forming cement clinker using mill scale that may have hydrocarbons associated therewith. Normal feedstock material is preheated and then transferred to a combustion area. The mill scale is also transferred to the combustion area where, during the process of burning a material, the unwanted hydrocarbons are volatilized and converted to harmless gaseous products (by ....

Cement mill process

May 18 2018Cement Mill Process The Cement Mill Process has different Stages in Cement Production and they are The raw materials of Cement Mill Process are lime and silica Alumina and ferric oxide are used as fluxing agents Collection of raw materials such as lime stone This is transported to the mill site and crushed there if the quarry is far off. LATEST CASE . umesh stone crusher ; Dealer ......

Cement Manufacturing Process

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches....

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material Storage and Transportation 3. Proportioning 4. Raw material Grinding and Transportation 5. Raw meal storage, ....

Mercury Speciation and Mass Distribution of Cement ...

Cement production process of Plant 2 Raw mill E004 Raw mill system Rotary kiln E002 Rotary kiln system Sampling site 1 Cyclone collector A002 367℃ 95℃ 105℃ 103℃ 63℃ 95℃ 800~1000℃ 1250~1400℃ 100~300℃ 212℃ 367℃ Limestone 410℃ Iron cake Silica sand Clay Coal ash Waste lime Calcium fluoride sludge Raw materials Fuels Raw materials flow Gas ....

Manufacture process of cement Step by Step Description

Manufacture process of cement . 1) Mixing of raw material:A materials like as limestone or chalk and shale or clay may be mixed either in dry condition or wet process of according is known as dry process or wet process of mixing. a) Dry process: A dry process, the raw materials are first reduced in size of 25mm in current of dry air is then passed over the dried ......

cement manufacturing

Cement grinding. The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement. Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 – 4000 Blaine surface (cm2/gm)....

milli microns and cement grinding

process diagnostic studies for cement mill The various types of grinding systems currently being used for cement grinding in a cement plant are: • Conventional tube mill Open and Close circuit • Tube mill with precrushing unit vertical shaft impactor (VSI) or horizontal impact crusher (HIC) • Roller press in semi finish and finish grinding mode get price...

Ujjain ball mill processing cement clinker Manufacturer ...

Cement Clinker Processing Machinery. Coal Mill is the main equipment of the rotary kiln cement clinker production system and at the same time also suitable for powder grinding equipment system Lime Kiln Cement Mill Processing capacity 65135 th Product specifiion m. Oline Chat...

flow daigram of raw mill in cement plant

Figure 1 – Flow diagram of cement process ... Fig 2 Raw mill process flow. 3. Get Price. Process Flow Diagram for Portland Cement Manufacturing ... Oct 22, 2014 ... The Cement Industry Members of Group H, for CHE 581 Supervised By ... In the wet process, water is added to the raw mill during the grinding... Get Price. Rawmill Wikipedia, the free encyclopedia . Rawmix is then fed to a ......