Vibrating Feeders Feeding Lump Size

Designing a Hopper

Material properties Size distribution, bulk density, shear properties and cohesive strength are the main factors that dictate the configuration of Feeder Transition design. These factors, in conjunction with feeder stroke, stroke angle, and feeder vibrating frequency, affect how well material flows from the hopper to the feeder and through the feeder. Failing to consider material properties ......

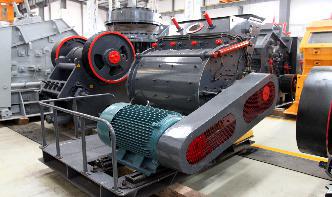

ZSW Series Vibrating FeederVanguard Machinery

VANGUARD's ZSW Vibrating Feeder can be used to feed various ores stones river pebbles construction wastes and other lump and granular materials. The feed chute is equipped with single layer of grate bars which can simply prescreen the materials to remove the fine materials and sundries in the raw materials. ZSW Vibrating Feeder adopts double eccentric shaft vibration exciter. which is of ......

How to Apply Heavy Duty Apron Feeder

Heavyduty apron feeder is widely employed in mining, metallurgy, electrical power, coal, etc industries due to its large feeding capacity, will withstand the direct impact of the massive lump materials and also the stable performance. heavy apron feeder can convey a spread of bulk materials on a horizontal or inclined direction(the most inclination Angle of upward transportation is 25 ......

Eriez

Eriez Light and Medium Duty Electromagnetic Feeders. Eriez' unique HiVi magnetic drive circuit provides a simple yet powerful solution to difficult material feeding appliions. These feeders, with their totally enclosed patented magnetic drive, can feed practically ....

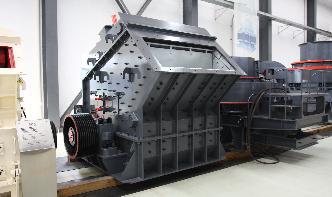

VIBRATING, GRIZZLY PAN FEEDER | RTechno

Vibrating, Grizzly Pan Feeder. Vibrating, Grizzly Pan feeder is suitable to feed crushers, selecting the large sizes which require primary crushing, the smaller sizes, and any fines which must be eventually rejected. RTECHNO Grizzly is used to transfer the large size materials and granular materials from hopper to receiving device uniformly, periodically and continuously in the production ......

Feeder | Ore Feeder | Vibrating Feeder | Vibratory Feeder ...

GTEK Feeder Description. Feeders can feed lump or granulated materials to the other devices evenly and continuously. In mineral and gravel production line, the continuous feeding of the vibrating feeding machine helps avoid the blockage at receiving hopper. With easy flow adjustment, low noise and energy consumption. Appliion. Feeders are applied to crushing and screening production lines ......

ELEKTROMAGJOEST | Hopper Discharge Feeder (magnetic channel)

Magnetic feeders are therefore especially useful for dosing (weighed feeding). Various parameters have to be considered in the system's design and configuration, such as hopper pressure, hopper geometry, particle size, flowability, humidity, tendency to caking, etc. Hopper discharge feeders are therefore designed individually for each appliion....

How to Design Efficient and Reliable Feeders for Bulk Solids

Vibrating Pan Max. practical particle size Up to 1/3 of min. pitch1 6 in. 1/2 in. 12 in. and larger Particles degrade (attrit) easily Fair Good Fair Good Material is a dry powder Good Fair2 Excellent Poor2 Material is sensitive to overpressure Fair Good Fair Poor 1 Depends on feeder robustness. 2 When used with slide gate for initial fill. Table II: Feeder Selection Based on Appliion ......

Screen

Vibrating feeder is another mining equipment used to feed certain amount of materials lump, grain or power from inventory to receiving devices in different stages. It's suitable for crushing, beneficiation etc. Kunming Ciba Mining Machinery Co., Ltd. is capable of designing and manufacturing vibrating linear and circular screens, grizzly screen and vibrating feeder. They have multiple models ......

GZD Series Vibrating Feeder

The GZD Vibrating Feeder is the tool feeding the lump, granular and powdery materials from the warehouse or hopper into the material receiving equipment in a uniform and continuous manner or by certain amount. In crushing lines, this product can feed the materials in a continuous and uniform manner to the crushing machine and screen the materials primarily. Materials: Granite, marble, basalt ......

MVGH Horizontal Vibrating Grizzly Feeder | Minyu Machinery ...

· Just like the MVG Feeders, the Minyu Horizontal Vibrating Grizzly (MVGH) Feeders are designed for regulating the feed rate to the crusher by separating the materials for sizing, removing the unwanted, and bypassing the smaller for the crusher so as to maximize the crushing capacity. However, the MVGH Feeders come in lower profile and longer in length. They are generally applied for portable ......

Feeding the facts 1/3: Apron feeder basics

· Limitations on size and type of ore. Apron feeders do have limitations when it comes to the size and type of ore. The size and type limitation will vary, but there should never be senseless dumping of material onto the feeder. You will need to not only factor in the appliion you will be using the feeder for, but also where in the process this feeder will be placed. Generally, an industry ......

A FULL RANGE OF PROVEN FEEDERS AND THE PEOPLE TO .

allows dumping of big lumps directly onto the feeder pan. •Vibration free operation and small dynamic loads. • Powerful hydraulic drive gives mini easy capacity adjustment from zero to as well as immediate stop of material feed after stopping signal. • Can handle heavy and moist material and unlimited feed material height allows the installation directly under high ore bins or ......

WorldClass Apron Feeders

Minerals custombuilds feeders to handle nearly any lump size and type of material. 2 Truck dump hoppers utilize the World Class Apron Feeder to withdraw rock and ore at a controlled rate of speed to feed other equipment such as impact crushers or vibrating grizzlies. 3 Minerals manufacturers Apron Feeders of various size, tonnage and drive configurations to meet the specific ......

Vibrating Feeder working principle/technical parameters ...

· Product Introduction. Vibrating Feeder is also known as vibrating feeding machine; it could put lumpish, granular materials into material accepting device uniformly, timely and continuously from silos during the production process, it could feed for crusher machinery continuously and evenly in gravel production line, and coarse screening the material, widely used in the crushing and screening ......

your vibrating equipment specialist

Pan sizes range from m wide x m long to m wide x m long, with proven flow rates of up to 4 800 m3/hr. This makes the Vibramech Feeder the ideal solution for most feeding appliions. All feeders and associated chute geometries are assessed together with the client. This ensures a troublefree and reliable feeding solution....

Vibrating Feeder

Vibrating feeder can feed lump or granulated materials to the other devices evenly and continuously. In sand and gravel production line, the continuous feeding of the Vibrating feeder helps avoid the blockage at receiving hopper. With easy flow adjustment, low noise and energy consumption, vibrating feeder is applied to crushing and screening production lines on crushing site, in mining ......

Grizzly Feeders HeavyDuty Pan Feeders

• Maximum lump sizes can range up to 6' cubes • Fines pass through the grizzlies, relieving the crusher and reducing wear • Vibration is generated by precisionmachined, twin eccentric shafts • The vibrating drive assembly is connected directly to the pan to assure positive action under the most adverse loading conditions. H eavyd uty P an F eeders Pan Feeders • Heavyduty feeders ......

WT1200 – Weigh Belt Feeder Operation and Installation Manual

product lump size. Lump Size The shear gate must be set to times the diameter of the max lump size. Capacity The shear gate height setting must allow sufficient product volume to pass at max belt speed. Turn Down Ratio Web Tech specifies a max turn down of 10:1 to avoid the use of a cooling fan. Forced fan cooling and...

Grizzly Feeders, Manufacturer Exporter of Grizzly ...

VIBRATING FEEDER WORKING PRINCIPLE: ... Grizzly Feeders are designed to handle run of quarry stone up to 1000mm lump size. The plain section is lined with a minimum thick replaceable plate in mild steel as standard, with abrasion resistant manganese steel and rubber elements as options. BELOW DECK VIBRO MOTOR MOUNTED TYPE: The Grizzly feeder is suitable to feed primary jaw ....