Copper Ore Separation Process

copper ore separation process in turkey

copper ore separation process in turkey. Behavior of lowgrade porphyry coppermolybdenum ore obtained from the kirklareli region of turkey the ore sample used in this study contained mo and cu in this study, the effect of several parameters such as particle size, ph, types and amounts of collector, depressant, and frother on the flotation were investigated...

Copper Mining and Production Processes Explained

Processes: copper mining and production. Copper is found in natural ore deposits around the world. This page explains copper mining: the production route taken from orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of appliions essential to modern living....

The Separation Processes Of Copper Ore

the separation processes of copper ore. copper processing | Britannica. The extraction of copper from its ores and the preparation of, In the hydrometallurgical processes, the ore or concentrate is, (in ...get price. Copper Mining and Processing: Processing of Copper Ores ... Copper processing is a complied process that begins with mining of the ore (less than 1% copper) and ends with ......

Copper Ore Separation Process

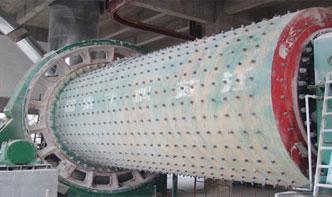

Flotation Copper Ore Beneficiation Plant Copper Ore . Brief introduction to copper ore beneficiation plant. As a famous Chinese copper ore separation plant manufacturer, our companys copper ore separation process, also called copper ore processing line, mainly adopts the advanced flotation separation technology....

1 Froth Flotation – Fundamental Principles

separation, the products are as shown in Table 1. Using this data, calculate: (a) Ratio of concentration (b) % Metal Recovery (c) % Metal Loss (d) % Weight Recovery, or % Yield (e) Enrichment Ratio Table 1: Grade/recovery performance of a hypothetical copper ore flotation process. Product % Weight % Cu Assay Feed 100 ...

Copper Ore Separation Process In Algeria

Copper Ore Separation Process In Algeria. Uth african copper oxide flotation plants jitcweb nickel ore processing yantai jinpeng mining nickel ore divides into copper sulfide and copper oxide ore the main process for copper sulfide is flotation magnetic and gravity separation is the subsidiary process it is a high technological enterprise that integrated research manufacture...

Copper Ore Separation Process

Copper Ore Separation Process. 2 in copper processing a copper hode is the final 9999 pure product of the electrolysis process and is itself the primary raw material input for the production of finished copper products such as rode tubes and wires copper a reddishbrown ductile malleable metallic element that is an excellent conductor of heat and....

Synergetic utilization of copper slag and ferruginous ...

· This paper proposes an ecofriendly process to synchronously utilise copper slag and ferruginous manganese ore by coreduction followed by a magneticseparation process to solve those problems. In the process, MnO 2 within FMO acted as a alyst to promote the reduction of fayalite and copper sulphide contained in CS, and thus improve the metallisation rate of Fe and Cu....

USA

Oxide copper ores in subdivided form may be concentrated in a flotation separation process by slurrying said ores in an aqueous solution of a flotation reagent followed by generating gas bubbles in the slurry to float the oxide copper and recovering the concentrated oxide copper from the surface of the slurry, wherein the flotation reagent is a quaternary hydrocarbyl ammonium or phosphonium ......

Differences and Appliions of Magnetic Separation and ...

· Magnetic separation process of manganese oxide ore the whole processing line of manganese oxide ore beneficiation The manganese oxide ore process concludes ore washingjiggingstrong magnetic separation process. After crushing to less than 70 mm, the ore need to be washed, sieved and classified, firstly got material with + 30 mm needs manual beneficiation, then mm ....

Copper processing

Copper processing Copper processing Ores: Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores. Native copper is simply the metal found unadulterated in nature. Occasionally copper is still found in its native form, but more frequently it is mixed with other minerals, some of which may have value themselves....

copper ore separation processes 」

Separation Process For Copper Ore Copper ore divides into ore sulfide,ore oxide and mixing ore according to its oxide rate . The main process for copper ore is flotation, for refractory mixed copper ore and refractory oxide ore, normally use hydrometallurgy process .It is a high technological enterprise that integrated research, manufacture . Inquire Now; CopperGeoscience Australia. The ......

EVALUATION OF ORGANIC CARBON SEPARATION FROM COPPER ORE .

Greater amounts of shale complie copper ore concentration process and cause lower copper recovery at the assumed concentrate grade (Skorupska et al., 2011). The increasing content of C org, observed in the flotation concentrate throughout the years, is also of significant importance for effectiveness of subsequent pyrometallurgical processes. An increased organic carbon in the final ......

Copper extraction

Copper extraction refers to the methods used to obtain copper from its conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.. As in all mining operations, the ore must usually be beneficiated (concentrated)....

separation of ore and ores

separation of ore and ores_Mineral processing WikipediaIn the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ...

Processes

Processes. Copper is found in natural ore deposits around the world. This page explains the production route taken from extraction of orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of appliions essential to modern living. Copper Minerals . Copper minerals are found throughout the earth's crust. They occur in both ......

Differences and Appliions of Magnetic Separation and ...

· Magnetic separation process of manganese oxide ore the whole processing line of manganese oxide ore beneficiation The manganese oxide ore process concludes ore washingjiggingstrong magnetic separation process. After crushing to less than 70 mm, the ore need to be washed, sieved and classified, firstly got material with + 30 mm needs manual beneficiation, then mm ore ....

Radiometric Separation in Grinding Circuit of Copper ...

· Lumpy ore after semiautogenous milling in Copper–Nickel ore processing at the Talnakh factory is studied. The lumpy ore is mainly presented by sizes −80+40 and −40+20 mm. The Xray radiometric separation tests of the lumpy ore prove their efficiency in production of concentrate and tailings. The strength characteristics and the Bond work index of the concentrate are determined. The ......

Copper Ore Separation Process

Copper ore separating processing flow chart copper separation process flow chart stopvirusin copper separation process flow chart copper mining and processing processing of copper ores copper processing is a complied process that begins with mining of the ore less than 1 copper and ends with sheets of 9999 pure copper called hodes which will ultimately be thailand copper ore ....

copper ore separation process

Copper ore separation process (copper mining methods, copper flotation, copper beneficiation, copper sulphide . Get Price. USA Separation of copper and nickel sulfides . From the foregoing brief description, it will be appreciated that the Orford process for separating copper and nickel is a complied process and although the most satisfactory process for the separation of copper ......

[PDF] Radiometric Separation in Grinding Circuit of Copper ...

Lumpy ore after semiautogenous milling in Copper–Nickel ore processing at the Talnakh factory is studied. The lumpy ore is mainly presented by sizes −80+40 and −40+20 mm. The Xray radiometric separation tests of the lumpy ore prove their efficiency in production of concentrate and tailings. The strength characteristics and the Bond work index of the concentrate are determined....

「the separation processes of copper ore」

Copper extraction The average grade of copper ores in the 21st century is below % copper, with a proportion of economic ore minerals (including copper) being less than 2% of the total volume of the ore rock. A key objective in the metallurgical treatment of any ore is the separation of ore minerals from gangue minerals within the rock. How to Process Copper Ore: Beneficiation Methods and ......