Of A Hammer Crusher

How Many Types of Hammer Crusher Heads? The Most Wearable ...

· This crusher hammer is widely used in large limestone crushers for dry cement production lines. The high manganese steel crusher has good toughness, good manufacturability and low price. Its main feature is that its work hardening index is seven times higher than other materials. However, the hammer head of the highmanganese steel crusher has higher requirements for the overall ....

Hammer crusher hammer head,Mill liner,Wearresistant ...

Crusher hammer head, high chromium composite hammer head, forging hammer head, hammer crusher accessories, high chromium cast iron parts, professional casting company, is the experimental base of the Ministry of Industry and the Material Protection Engineering Research Center, and the national base. No. 3, Row 2, Yugongquan Industrial Park, Fengquan District, Xinxiang City, Henan ....

Hammer | Crusher Blog

· Hammer is one of the core components, which is arranged in the rotor shaft, hammer crusher at high speed in a direct blow to the material, eventually breaking into the appropriate particle size. Hammer manufacturing process is a key factor to determine hammer's life. If the manufacture of surface or internal defects such as shrinkage, cracks,....

Hammer Crusher

Hammer crusher has the characteristics of simple structure, large crushing ratio, high production efficiency, etc. It can be used for dry and wet crushing. It is suitable for medium hardness and brittleness in mining, cement, coal, metallurgy, building materials, highways, combustion and other departments. YouTube. JXSC Mining Machinery Factory....

doubleshaft hammer crushers

TITAN® doubleshaft hammer crusher with grate basket carrier Pentagonal rotor shaft for a TITAN ® crusher, type 60D160 Perfect material thanks to rotating hammers 4 ®TITAN doubleshaft hammer crushers 5. From top: Spare parts store thyssenkrupp control and diagnostic system Whether the spare parts are to be col lected by the customer or by air freight, we liaise with you to find the ......

HMM

The hammers are loosely suspended between the discs by means of screw connections with the shaft. The hammer arms are made of high quality steel and are easy to service. The hammer heads are wear parts made of material designed for the appliion and can be easily replaced. The grinding walls can be mechanically or hydraulically adjustable to compensate for wear and to achieve the desired ......

In case of a hammer crusher

In case of a hammer crusher, a) Crushing takes place by impact breaking b) Maximum acceptable feed size is 30 cms c) Reduction ratio can be varied by adjusting the distance from cage to hammers ....

CNA

The invention discloses a kind of reversible formula hammer head of hammer crusher, it includes that hammer body, gusset and lasso, described lasso are three, and is distributed on circumference;Described hammer body is with potassium steel as matrix, integral with three lasso castingins respectively;Described hammer end facial contour is circular, and the center of circle of ....

Balancing Of Hammer Crusher | Crusher Mills, Cone Crusher ...

hammer crusher design – Crushing Plant – Cruher and grinder . Our unique design concepts ensure our products the perfect balance . Hammer crusher for fine and medium crushing are designed with reverse operation of the rotor and . The Scientific Management of Hammer Crusher | CNC . The hammer crusher is a kind of crushing equipment with highspeed rotation. The strong ......

PCD Ulrtafine Hammer Crusher

PCD Ultrafine hammer crushers combine the technical advantages of crushing equipment at home and abroad, through development and improvement to make the stru......

Impact Crusher

Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing it to shatter causing further particle size reduction. This crusher produces more rounded shape. • Gyrating or cone crusher: It uses a repeated compression action with fixed and moving crushing members. This kind of crusher ......

Hammer Mills

Industrial Hammer Mill Crusher Appliion Usage. Agricultural Industry: Common appliions include crushing animal tankage, animal feed, grains, and agricultural limestone; Energy Industry: Reduce the size of materials such as coal, corn, bagasse, wood, corn stalks, biomass and biofuels, and more; Aggregate Industry: Common materials that hammer mills can finely crush include gypsum, shells ......

Crusher

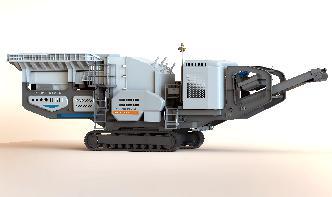

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated....

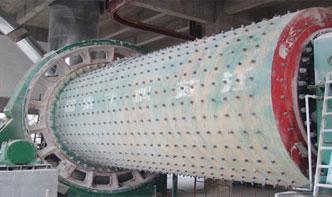

Hammer Crusher Working Principle | Hammer Crusher Parts ...

Hammer crusher mainly breaks materials by the impact of hammers. The material entered into the working area of the crusher is crushed by highspeed hammers. The crushed material obtains kinetic energy from the hammers, and then it impacts on the crushing plate and grate screen at high speed and is broken for the second time. After that, the material smaller than the gap of the grate screen is ......

Hammer Mills for Material Reduction | Williams Patent Crusher

HAMMER MILLS. Williams Patent Crusher is a leading industrial hammer mill manufacturer. Our industrial size reduction machines can handle any material size reduction job. Choose a Williams machine for high efficiency and economy. Using midair and impact crushing, grinding, and shredding, our machines can handle virtually any material....

Hammer crusher SMD147 A

Hammer crusher SMD147 A. A hammer crusher is used for the preliminary crushing of non abrasive fragile minerals of low and medium hardness (limestone crushing, chalk crushing, gypsum crushing, asbestos ore crushing, broken brick crushing, coal crushing, clay crushing, marl crushing, hard lime crushing, etc.) with the moisture content of not more than 810%....

A hammer crusher (Patent) | ETDEWEB

misc{etde_, title = {A hammer crusher} author = {Grishakov, N M, and Fedotochkin, U M} abstractNote = {The subject of this invention is a hammer crusher used to crush primarily samples of fibrous peat; it contains a frame with a feed head and a crushing chamber which contains a rotor with hinged hammers and a drive mechanism. In order to increase the operational possibilities of the ......

Crushers

A hammer crusher is suitable for midhard and light erosive materials such as coal, salt, chalk, gypsum, limestone, etc. Coal Hammer Crusher Operating Principles. Hammer mills are primarily steel drums that contain a vertical or horizontal crossshaped rotor mounted with pivoting hammers that can freely swing on either end of the cross. While the material is fed into the feed hopper ......

using a hammer for crusher | TreasureNet 🧭 The Original ...

· For the crusher/hammer part, an axle like mentioned above works well and doesn't flake. It is heavy and you don't have work so hard to slam it down. For small stuff I used to use a piece of 3 1/2" round stock. It was heavy!...

USA

A hammer crusher having a housing within which is journaled one or more rotatable hammer shafts cooperable with an anvil and gratings, each grating including replaceable grating bars. The grating bars are accessible for replacement by being mounted on a carrier movable into and out of the housing along a substantially horizontal path and without requiring appreciable lowering of the carrier to ......

What are the major parts of hammer crusher?

Answer: Hammer mill is now the absolute most commonly utilised mill and among the earliest. Hammer mills contain a succession of hammers hinged to a central shaft and included inside of a stiff metal case. It generates size decrease from impact. The materials to become milled are struck from thes......

The Characteristics Of 4 Types Of Hammer CrushersCLIRIK ...

The hammer crusher mill machine crushes materials by impact energy. The hammer crusher has a large crushing ratio (generally 1025, up to 50), high production capacity, uniform finished products, less overpowder phenomenon, low energy consumption per unit product, simple structure, light equipment, easy operation and maintenance, etc. It is one of the most commonly used machinery in the ......

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

crusher,Jaw crusher and Impact crusher. Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor,hammers, casing,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity. Impact crushers: they involve the use of impact rather than pressure to crush materials. The material is contained within a cage ......

EME

Doubleroll crushers can be used for small containers or as a second stage after a hammer crusher. The container passes between two rotating drums that have a specially designed lowwear surface structure. This type of crusher is capable of producing a defined particle size distribution. The crushing surfaces can be exchanged as required. As a result of its particular principle of operation ......