Processing Oxide Lead Zinc Ores

Lead zinc ore processing plant

Leadzinc ore processing equipment specific flotation process is as follows (for reference only) A. Grinding argillaceous zinc oxide ore, so that the particle size of accounts for 50% to 80%; B. Flotation of lead oxide by grading and overflowing of the finely divided slurry;...

processing of zinc ores

CopperLeadZinc ores Danafloat HomeThe CuPbZn separation process is among the most challenging flotation separations primarily because the first step must entail bulk flotation of the two moprocessing of zinc ores...

Efficient flotation recovery of lead and zinc from ...

· Labscale experiments results show that the new process contributed to the flotation of the complex mixed sulfideoxide lead and zinc ore regarding two aspects: (1) High alkaline process (pH = 12±) was replaced by low alkaline process (pH = 9±) by using collector WS (a mixture of ethyl thiocarbamate, ammonium dibutyldithiophosphate and dithiophosphate25) and combined depressant ....

2ZnS 3O 2ZnO SO2 (1)

importer of refined zinc. Zinc ores typically may contain from 3 to 11 percent zinc, along with cadmium, copper, lead, silver, and iron. Beneficiation, or the concentration of the zinc in the recovered ore, is accomplished at or near the mine by crushing, grinding, and ....

Five flotation methods, help you processing leadzinc ...

· Five flotation methods, help you processing leadzinc oxide ores. 16:08:29 XinHai (5803) Leadzinc ore is an important nonferrous metal resource with a wide range of uses. At present, most of the lead and zinc are obtained through the separation of leadzinc sulfide ore. ......

Beneficiation process of Lead Zinc(Zn) Ore

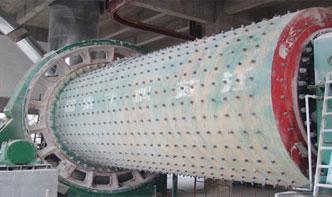

Beneficiation process of Lead Zinc (Zn) Ore. Ore mining jaw crusher initially preliminary broken, broken to a reasonable fine in the postdegree via elevator, vibrating feeder evenly into the ball mill, the ball of the ore crushing, grinding. After ball mill grinding of ore fines into the next process: classifiion....

DECISION Approving the master plan on exploration ...

Crnde and pure lead and zinc ores and material zinc oxide powder (containing percent of zinc) will not be expo1ted. Lead and zinc ore exploitation and processing investment projects shall be associated with specific (lead and zinc metallurgy) establishments according to the master plan....

A Manual On The Processing And Export Of Lead, Zinc And ...

A Manual on the processing and export of Lead, Zinc and Copper ores. For the benefit of those who need to know, an attempt would be made to define mineral and metal ore. Mineral is an inorganic substance found in nature with a characteristics chemical composition and in ....

processing oxide lead zinc ores

Lead And Zinc Ore Concentration Mill Process Chart. Mixed Sulphide–oxide Lead And Zinc Ores: Problems And Aug 01, 2011 1. Introduction. The minerals of lead and zinc are naturally associated with each other. Three types of mineralization may be distinguished for every lead and zinc deposit (i) ......

Flotation Conditioners of Oxidized Zinc and Lead Ore | CNFREE

· When the oxidized zinc ore is floated with an amine collector, it is difficult to separate the gangue minerals mainly composed of zinc oxide and calcium magnesium carbonate. At the same time, the presence of ore slime also affects the flotation using amine collectors....

Processing Oxide Lead Zinc Ores

Processing Oxide Lead Zinc Ores. Aug 21 2020 according to the international lead amp zinc study group refined zinc production reached about 128 million tons or about 28 million pounds in 2017 the ten largest refiners include both companies that mine and refine their own zinc ores as well as refiners that purchase from independent mines....

Development of a viable process for the T recovery of zinc ...

Development of a viable process for the recovery of zinc from oxide ores by de Wet* and Singleton * Synopsis The Skorpion Zinc Project demonstrated the viability of the production of zinc from nonsulphide (commonly called 'zincoxide') ores, using the ....

leadzinc ore

· 01 Recovery of zinc oxide ore from leadzinc ore tailings Spiral chute deslimingShaker enrichment Gravity selectionflotation. For the recovery of zinc oxide, the sludge must be controlled, because the sludge inhibits the floatability of zinc minerals, leading to a sharp increase in the amount of flotation reagents....

British Library EThOS: Hydrometallurgical processing of ...

Mixed sulphideoxide lead and zinc ores are most often found in the transition, and occasionally in the oxidised, zones of leadzinc ore bodies. They are of great importance because there are numerous unexploited or abandoned reserves of these ores in the world....

zinc processing

zinc processing zinc processing Ores: Zinc ores are widely distributed throughout the world, although more than 40 percent of the world's output originates in North America and Australia. The common zinccontaining minerals are the zinc sulfide known as zinc blende or sphalerite (ZnS), a ferrous form of zinc blende known as marmatite [(ZnFe)S], and a zinc carbonate known as calamine ....

Zinc smelting

Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc. Zinc smelting has historically been more difficult than the smelting of other metals, iron, because in contrast, zinc has a low boiling temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace with the flue gas and be lost, unless specific ......

processing oxide lead zinc ores

Oxide Metal is largest private producer of Lead and Zinc concentrate in Turkey which is integrated in mining, mineral processing of ores, smelting of Lead and Zinc ingots and trading of base metals. How to Process LowGrade Lead Zinc Ore by Flotation...

CNA

The invention relates to a method for pretreating ore pulp in a lead and zinc oxide flotation process. In the method, after a pH regulator, an inhibitor and a collector are added in turn before the rough concentration of lead and zinc oxides, stirring and pulp regulating are performed respectively, pulp regulating is also performed before the concentration of rough concentrate and before the ......

Oxide Lead Ores

Oxide Lead Ores Release time: Flotation reagents|Mining chemicals|Mineral Processing_SHENYANG FLORREA CHEMICALS CO., LTD 347...

Sulfide Oxide Lead Zinc Transitional Ore Treatment ...

· Leadzinc minerals present were small amounts of galena, cerussite, pyromorphite, hemimorphite, smithsonite, and a trace of sphalerite. Table 1 shows distribution of the leadzinc minerals. In this report the term oxide lead refers collectively to both cerussite and pyromorphite, and the term oxide zinc to smithsonite and hemimorphite....

Lead and Zinc Smelting

allurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter. Lead concentrations can be 50–70%, and the sulfur content of sulfidic ores is in the range of 15–20%. Zinc concentration is in the range of 40–60%, with sulfur content in sulfidic ores in the range of 26–34%....

LEAD ZINC EXTRACTION PROCESSES

are used for production of lead zinc depending on the type of raw material used as a charge. In the pyrometallurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter. Lead concentrations can be 5070%, and the sulfur content of sulfidic ores is in the range of 1520%....