Modeling And Control Of Cement Grinding Processes

process of cement grinding in iran

Modeling And Control Of Cement Grinding Processes In Iran. Modeling And Control Of Cement Grinding Processes In Iran. 5cement industry has been always among the largest co 2 emission sources. almost 57 of global co 2 emissions are caused by cement plants while 900 kg co 2 is emitted to the atmosphere for producing one ton of cement. in this work global strategies and ......

Modelling and optimization of grinding processes ...

The paper describes different methods for modelling and optimization of grinding processes. First the process and product quality characterizing quantities have to be measured. Afterwards different model types, physical–empirical basic grinding models as well as empirical process models based on neural networks, fuzzy set theory and standard multiple regression methods, are discussed ......

Intelligent Modeling and Predictive Control of Pre ...

Stably controlling the pregrinding process is paramount important for improving the operational efficiency and significantly reducing production costs in cement plants. Recognizing the complexity in both structure and operation of the pregrinding process, this paper proposed a fuzzy and model predictive control system to stabilize and optimize the pregrinding process....

Air Pollution Control in the Cement Industry

Portland cement manufacturing plants both old and new loed in congested and sparsely populated areas of the country have, for many years, installed the most modern and efficient emission control available at the time. The process of ....

Cement Manufacturing Process

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches....

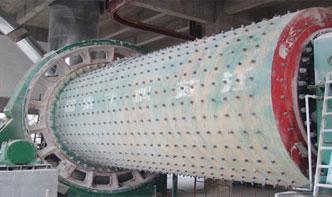

Modeling and Optimization of Cement Raw Materials Blending ...

Before cement raw materials are transported into the cement burning kiln, cement raw material blending process is considered as a whole process, thus the grinding process could be seen as part of blending process. For integrity and generality, we consider that the cement raw material blending process includes ball mill grinding process. Then, the mass balance equation of active ingredients SiO...

Manufacturing of Portland Cement – Process and Materials ...

· The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular shaped clinker by broking of chemical ....

Modeling and Numerical Simulation of the Grinding ...

Xu et al. conducted the minimum cuttingin (5 μm) grinding contrast experiment on the precise DC grinder with the water droplets processing liquid attached by minimum quantity oil film, emulsion solution, soluble concentrates, minimum quantity spray and minimum quantity oil mist processing liquid. Furthermore, they measured the grinding force, surface roughness, the ....

Modelling and Simulation of Grinding Processes

· Aeynore raper Modelling and Simulation of Grinding Processes H. K. Tonshoff (l), J. Peters (1). I. lnasaki (l), T. Paul Abstract This paper describes the stateoftheart in the modelling and simulation of grinding processes. The kinematics of the grinding process are characterised by a series of statistically irregular and separate engagements....

Throughput optimisation in milling circuits

Advanced Control Process. A good advanced control system such as MillStar can significantly increase throughput and grinding efficiency. Additionally, the liner and lifter life can be extended and the percentage grinding media per ton of ore processed can be reduced. Controlling the feed and discharge of a mill is mostly a stabilisation ......

Impacts of Cement Industry on Environment

Pollution control in the cement industry pushes forward this industry to do something about the reduction of the pollutants produced by the manufacturing and handling of ....

Integrated Modeling and Intelligent Control Methods of ...

· The grinding process is a typical complex nonlinear multivariable process with strongly coupling and large time delays. Based on the datadriven modeling theory, the integrated modeling and intelligent control method of grinding process is carried out in the paper, which includes the softsensor model of economic and technique indexes, the optimized setpoint model utilizing casebased ......

Impacts of Cement Industry on Environment

Pollution control in the cement industry pushes forward this industry to do something about the reduction of the pollutants produced by the manufacturing and handling of cement, lime and gypsum ......

Modeling of the Thermal Efficiency of a Whole Cement ...

technology" and other e orts to develop production lines with external processing of coal grinding and raw meal drying to retrieve the thermal energy exiting the flues [10–13]. It is worth noting that research has been recently conducted to develop intelligent control tools for the same purpose [14–18]. For cement clinker calcination systems, improving thermal e ciency is the most ......

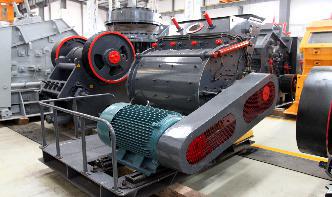

Predictive Control of a Closed Grinding Circuit System in ...

operation of the cement grinding circuit, which allow the minimization of the final product variability, while reducing the energy consumption at this stage. Many contributions have been made in the control of grinding circuits. For instance, reference [3] proposes a dynamical model of the grinding process to tune the PID controllers...

Carbon Dioxide Control Technologies for the Cement Industry

2. The cement clinker burning process 3. Assessment of carbon dioxide control technologies Precombustion technologies Oxyfuel technology Postcombustion technologies 4. Preliminary research results (Oxyfuel technology) Impact on raw meal decarbonation Modeling of the clinker burning process with Oxyfuel operation...

(PDF) Modelling and Simulation of Grinding Processes with ...

Grinding tool topography is one of the several key aspects of the modelling of a grinding process. Simplifying it could mean less processing time needed, but ....

PROCESS CONTROL FOR CEMENT GRINDING IN

HOME / PROCESS CONTROL FOR CEMENT GRINDING IN. Relevant . hsi crusher manufacturers in india attributes of it in mining industry what is better crushed granite or limestone coal crusher paper 4 prong dryer outlet diagram palm kernel grinding machine in indian model washer dryer repair atlanta cost of quarry machine coal mining sequence rotary dryers homebase washing machine gravel cone ....

the process grinding of the cement

Cement Grinding Plant of the Year – ICR Cement Industry . The mill uses around 105t of Vega grinding balls to grind the clinker. Conscious of the plant's loion in an urban area, to reduce the noise of the grinding process, the mill building is covered in a special cladding to lower noise pollution by 32dB to 82dB when the mill is in operation....

Energy optimization in cement manufacturing

mizer (EO) to model the process and to identify the best possible way of running the plant at all times. Reducing energy demand in all areas must be com bined with the search for the optimal operating point that is consistent with productivity and quality targets. Variable Speed Drives – an electrical energy saver In the cement manufacturing process large fans draw air through the kiln ......

INVESTIGATION ABOUT THE EFFECT OF CHEMICAL GRINDING .

Cement manufacturing involves a grinding process of clinker, gypsum and secondary mineral additions, usually carried out in ball or vertical roller mills. Efficiency of grinding (in terms of energy actually used to increase cement fineness over total energy) is usually very low and reported to be in the range 1030%. Due to increasing interest in energy savings and high fineness cement ......