Bridge Concrete Crusher Concrete Crushing Process

What Process Is Used In Recycling Concrete? | Crushcon QLD

Recycling of concrete is a relatively simple process. It involves breaking, removing, and crushing existing concrete into a material with a specified size and quality. It is then put through a process of sorting and using a large powerful crusher the materials are actually crushed into concrete pieces. Embedded items such as steel are removed and any contaminants such as soil, glass and ......

The Complete Guide to Crushed Stone and Gravel

· However, they can also be used on bridge piers and river walls. Limestone: A sedimentary rock that is the most commonly used to make crushed stone in the United States. One of the most versatile rocks for construction, limestone is able to be crushed easily making it a primary rock used in ready mix concrete, road construction, and railroads ......

Particulate Matter Regulations Presentation

Nonmetallic Mineral Processing Equipment or Rock Crushers and Permitting changes for Concrete Batch Plants . Particulate Matter • PM represents a broad class of chemically and physically diverse substances. • Particles that are less than micrometers in diameter are known as "fine" particles; those larger than micrometers, but less than 10 micrometers, are known as "coarse ......

CreteCrush® | The EDCO Company Store

5Head CreteCrusher® 11, 10, Add to cart; Search for: Search. All orders are subject to a minimum. Cart. Product Categories. Clearance; Machines. MagnaTrap® Floor Grinders. MagnaTrap® DualDisc Floor Grinders; MagnaTrap® HeavyDuty Floor Grinders; MagnaTrap® SingleDisc Floor Grinders; MagnaTrap® Turbo Grinders; CretePlane® CreteCrush® Traffic Line ......

Impact Crusher

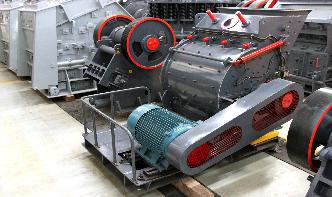

Different crushers have different consequences on the physical and mechanical properties of RAs depending upon the effectiveness of crushing processes [23] and consequently it affects the concrete performance also. Jaw crushers are mainly used for primary crushing as it can crush oversized concrete pieces into comparable size for secondary crushing. Impact crushers are preferred for ....

Constmach | Concrete Batching Plants Crushing And ...

CONSTMACH is the leader concrete batching plant, crusher and concrete block machine manufacturer of Turkey since its foundation, 2002. Cement silos, sand screening and washing plants, mobile crusher are other product types which are manufactured by CONSTMACH. CONSTMACH manufactures its products at its factory which is loed in İzmir,Turkey....

TSWB series PRIMARY CRUSHER – OKADA AIYON CORPORATION

Demolition crusher processes reinforced concrete structure. Concrete building, Concrete bridge, concrete foundation. Features. The special casting alloy used delivers a lightweight crusher with superior durability. Wider and deeper crushing area. The wedge arm penetrates concrete structures. The cylinder rod is protected by a rod cover. (Except for the TSW250, TSWB350, TSWB500V, TS ....

SmartCrusher bv

In addition to the existing SmartCrusher (crushing/milling) technology, additional technologies are under development that will make concrete completely circular. Read more about Concrete and the Environment. SmartCrusher as the solution, read why. News. Home ↑ The new SmartCrusher SC Published on December, 15th 2020• In close consultation with "launching customer" Fa. Rutte (SCP ......

Crushers

Designed for crushing soft and mediumhard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt appliions. Adjustable and interchangeable breaker plates enable grinding up to 50 percent with a durable rotor that can operate in both directions, lowering the ......

What is Crushed Aggregate? (with pictures)

Impact crushers are used to created crushed rock aggregate. The different aggregate sizes and types are appropriate for specific uses in the construction and landscaping industries. For example, although the larger, coarse crushed aggregates are more economical, this type of aggregate can present problems if used in concrete forms for upright structures....

Considerations when choosing a concrete crusher

· Impact crushers. While jaw crushers use compression to break up concrete, impact crushers use impact (as their name implies). Material is introduced into the crushing chamber, which houses a heavy ......

Aggregate Crushing PlantHigh Safety High Efficiency ...

Aggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system. As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the highrise buildings, the oldstyle buildings die out, and the waste of the construction wastes is directly buried without treatment, Then it ......

BAVCrushers

BAV Crushers: Demolition, Crushing and Screening Attachments for Excavator. BAV Crushers design and manufacture a range of concrete, brick and rubble crushing and screening attachments for excavators in recycling and demolition appliions. Our equipment is made in the United Kingdom and sold worldwide. BAV attachments are designed to help you work profitably on a wide range of tasks, ....

Crushing Plant Design and Layout Considerations

crushing plant costs can be as high as 18 million. It's necessary therefore to estimate crusher installation costs based on equipment costs plus the following direct costs, including construction contractor indirects: • Earthworks • Mechanical • Concrete • Electrical • Structural steel • ....

Resource Utilization of Construction Waste Mobile Crusher

· Mobile crusher is an essential machine used in the crushing process of recycling construction waste. It can realize construction waste disposal, converting it into renewable resources. The mobile crusher can not only solve the historical problem left by the rapid development of cities such as construction waste, but also further promote the green development of cities. Therefore, it is quite ......

Crusher

Crushing is the process of transferring a force amplified by mechanical advantage ... these crushed rocks are directly combined with concrete and asphalt which are then deposited on to a road surface. This removes the need for hauling over sized material to a stationary crusher and then back to the road surface. Types of crushers. Portable Close Circuit Cone Crushing Plant. Cornish stamps used ......

Concrete recycling

Crushing at the construction site using portable crushers is cheaper and causes less pollution than transporting material to and from a quarry. Large roadportable plants can crush concrete and asphalt rubble at 600 tons per hour. These systems normally include a side discharge conveyor, a screening plant, and a return conveyor from the screen back to the crusher for recrushing large chunks ......

New and improved jaw crusher from Kleemann | AggNet

· Kleemann introduce nextgeneration MOBICAT MC 110(i) EVO2 mobile primary jaw crusher. CAPABLE of outputs up to 400 tonnes/h, the newgeneration Kleemann MOBICAT MC 110(i) EVO2 mobile jaw crusher is designed for a wide variety of quarry and recycling appliions where the requirement is effective coarse primary crushing. Development of the new machine's tried and tested ....

5 Types of Concrete Crushers for Recycling Concrete Blocks ...

· Concrete block often appears after building and bridge demolition, which will cause problems like pollutions and land waste. There are mainly 5 types of concrete crushers like portable concrete crusher, mobile concrete crusher, small concrete crusher, excavator concrete crusher and bucket crusher, so you have to choose the right crushing machine according to your own situation....